1、JXF Large energy-saving continuous (internal heating) fluidized bed dryer

2、ZLG Linear vibrating fluidized bed dryer

3、XF and NXF boiling / continuous (internally heated) fluidized bed dryers

4、GFG High efficiency boiling dryer / FG boiling dryer

Introduction to fluidization technology

Concept of fluidization phenomenon: in an equipment, granular materials are stacked on the distribution plate in the equipment. When the gas flows into the material layer through the distribution plate from the lower part of the equipment, with the increase of air velocity to a certain extent, solid particles appear boiling on the distribution plate. This phenomenon is called fluidization, while the material layer is called fluidization layer, and the equipment is called fluidized bed. With this method and other technologies, the functions of material mixing, drying, granulation and coating can be completed.

Fluidization can be divided into dispersion and aggregation. Generally, most fluidized beds are aggregation fluidization. Aggregation fluidization: solid particles appear not in a single form, but in the form of particle clusters. In practical application, improper process parameters and equipment design are easy to cause "gully flow" and "surge". Experienced process parameters and structural design are more important to the success of the equipment.

(1) Channel flow: when the air flows into the bed, it is unevenly distributed, resulting in a short circuit in some parts of the bed, so that a considerable amount of fluid flows through the bed through the short circuit. If "channel flow" occurs, the drying medium will have poor contact with the dried materials, and the drying effect will be reduced.

(2) Surge: when the particle size distribution in the fluidized bed is uneven, the gas passing through the distribution is uneven, and the height and diameter of the fluidized bed are relatively large, the bubbles in the bed will converge and grow. When it is close to the inner diameter of the bed, the solid particles will form a piston to move upward in the bed, which will cause great damage to the bed, and will also cause poor contact between the solid particles and the drying medium fluid, The drying effect is reduced.

Advantages of fluidized bed: due to large contact area between material and drying medium, good heat transfer effect and relatively uniform temperature in the bed, it has high heat capacity coefficient (or volumetric heat transfer coefficient) and large production capacity; Continuous operation or intermittent operation can be carried out in the same equipment; The residence time of materials in the equipment can be adjusted as needed; The device has few moving parts, so the investment and operation cost of the equipment are low.

There are three states for airflow passing through the bed: V < VMF, VMF < V < VT, V ≥ vt

VMF – fluidization velocity at yesterday's boundary V – airflow velocity in the bed vt – settling velocity of particles in the bed

(1) In the first stage (fixed bed), when V is low (V < VMF), although the solid particles in the bed are in contact with the gas flow, the relative position of the solid particles does not change. At this time, the state of the fixed particles is a fixed bed;

(2) In the second stage (fluidized bed), when v gradually increases to a certain point (VMF < V < VT), the solid particles will produce irregular movement in the bed, and the bed is in fluidization at this time;

(3) In the third stage (airflow conveying bed), when v ≥ VT, the solid particles can not continue to stay in the equipment, but are brought out of the equipment by airflow.

The first stage is mainly drying, such as static drying of oven, belt conveyor, etc.

The second stage of industrial operation is used, that is, the functions of fluidized bed drying, granulation, mixing and coating.

The third stage is mainly various airflow drying, etc.

Different materials have different requirements for finished products. According to the principle of fluidized bed and the composition, principle and operation technology of each machine, select and design better equipment and adopt good operation technology, so as to obtain products with high cost performance.

1、JXF Large energy-saving continuous fluidized bed dryer

The large-scale energy-saving continuous fluidized bed drying production line obtains products without flying dust by continuously entering wet raw materials into fluidized beds (such as internal heated fluidized beds) for drying and cooling. An energy-saving fluidized bed system technology (in the process of patent application) is adopted. Compared with the ordinary continuous fluidized bed, it can reduce the exhaust volume of fluidized bed tail gas, make full use of the exhaust heat of fluidized bed exhaust, and the outlet materials have no dust flying, so as to improve the environmental protection of discharged tail gas, reduce the energy consumption of production line, no powder in outlet materials, improve the material yield, stable and safe operation High investment cost performance and low maintenance and operation costs.

The types include vibrating fluidized bed, horizontal multi chamber fluidized bed, internal heat exchange fluidized bed, high temperature fluidized bed, spout fluidized bed, etc.

The following processes can be realized: continuous drying and cooling of solid materials and high moisture absorption materials, continuous preparation and drying of powder raw materials, continuous drying, calcination and cooling of crystalline wet materials, and continuous preparation to solid particles from liquid raw materials.

In the hot air drying process of wet materials, there are mainly constant speed drying stage and reduced speed drying stage. The high humidity exhaust in the constant speed section and the front section of the reduced speed section of the traditional fluidized bed and the low humidity exhaust in the rear section of the reduced speed section are usually mixed together, resulting in the difficulty of using the heat contained in the exhaust.

After the traditional fluidized bed drying exhaust gas is separated by the dust removal system, the solid particle size obtained is small, which does not meet the particle size range of the finished product. It is usually necessary to add liquid for re dissolution and recrystallization. Recrystallization will directly have recrystallization loss. At the same time, the added liquid needs repeated drying, resulting in increased overall energy consumption.

The available technical scheme of the JXF energy-saving continuous fluidized bed dryer is:

1. An energy-saving fluidized bed system comprises a fluidized bed main body, in which a constant speed section drying area and a speed reduction section drying area are arranged, and the fluidized bed main body is provided with an air inlet, a high humidity exhaust outlet and a low humidity exhaust outlet, which is characterized in that the air inlet corresponding to the constant speed section drying area is connected with the constant speed section air inlet system, The air inlet corresponding to the drying area of the deceleration section is correspondingly connected with the air inlet system of the deceleration section, the high humidity exhaust outlet is connected with the air outlet heat exchange system for heat exchange with the fresh air, the outlet of the heat exchange fresh air of the air outlet heat exchange system is connected with the air inlet system of the constant speed section or / and the air inlet system of the deceleration section, and the outlet of the low humidity exhaust outlet is connected with the air inlet system of the constant speed section or / and the air inlet system of the deceleration section.

2. The main body of the fluidized bed is also provided with a cooling section fluidization area close to the discharge outlet, and the corresponding air inlet of the cooling section fluidization area is connected with the cooling section air inlet system.

3. Other contents can be communicated face to face.

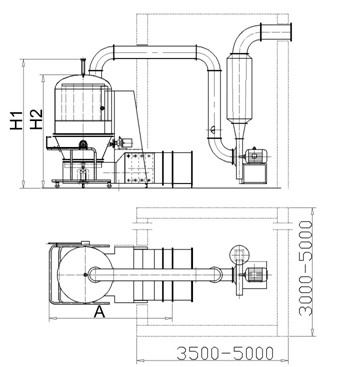

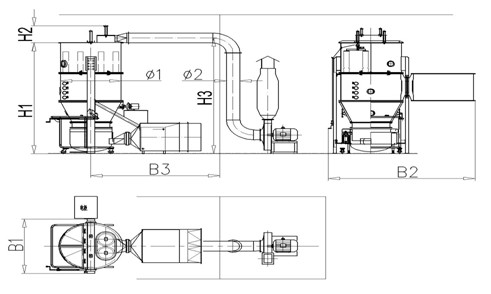

2、ZLG Linear vibrating fluidized bed dryer

Product information:

It belongs to a square fluidized bed and adopts the fluidized bed technology of vertical upward flow and vibration. The material moves forward continuously by jumping and throwing along the horizontal screen.

It is suitable for drying, cooling and humidifying powdery, granular, flake and fibrous materials in chemical, pharmaceutical, food, feed, mining, metallurgy, building materials and other industries. It can also be used for drying and cooling or cooling and humidifying at the same time. Such as citric acid, monosodium glutamate, borax, thiamine, compound fertilizer, shredded radish, soybean meal, distiller's grains, seeds, slag, granulated sugar, etc.

Equipment features:

The fluidization is uniform, without voids and blowing through, and uniform dry and cooled products can be obtained.

Good adjustability, wide adaptability, stepless adjustment of material layer thickness, moving speed and amplitude in the machine.

It has little damage to the material surface and can be used for drying fragile materials. When the material particles are irregular, it will not affect the working effect.

technical parameter:表一

| 型号specification | ZLG3×0.3 | ZLG3×0.6 | ZLG4.5×0.6 | ZLG6×0.6 | ZLG7.5×0.6 | ZLG7.5×1.2 | |

| 网板面积area of bed | m2 | 0.9 | 1.8 | 2.7 | 3.6 | 4.5 | 9 |

| 水份蒸发量capacity(130℃) | kg/h | 30 | 60 | 85 | 115 | 125 | 200 |

| 蒸汽压力 | MPa | 0.4-0.6 | |||||

| 激振力 | kgf | 500 | 800 | 800 | 1600 | 3200 | 5000 |

| 激振频率 | 次/min | 3000 | 3000 | 3000 | 3000 | 1500 | 1000 |

| 振动电机功率 | KW | 0.5×2 | 0.75×2 | 1.1×2 | 1.1×2 | 1.5×2 | 3×2 |

| 总功率 | KW | 6 | 7.5 | 10 | 13 | 17.5 | 34.5 |

technical parameter:表二

| 网板长 | 网板宽 | 床体宽 | 下床体高 | 上床体高 | 床体总高 | 重量(kg) |

| 3000(mm) | 300 | 1350 | 950 | 430 | 1700 | 1240 |

| 600 | 1650 | 950 | 430 | 1700 | 1400 | |

| 900 | 1950 | 950 | 600 | 1850 | 1630 | |

| 4500(mm) | 300 | 1350 | 950 | 430 | 1700 | 1570 |

| 600 | 1650 | 950 | 430 | 1700 | 1860 | |

| 900 | 1950 | 950 | 600 | 1850 | 2430 | |

| 6000(mm) | 600 | 1700 | 950 | 430 | 1700 | 2410 |

| 900 | 2000 | 950 | 600 | 1850 | 3160 | |

| 1200 | 2400 | 950 | 800 | 2050 | 3580 | |

| 7500(mm) | 600 | 2100 | 950 | 600 | 1850 | 4140 |

| 900 | 2500 | 1150 | 800 | 2040 | 5190 | |

| 1200 | 2850 | 1150 | 1000 | 2450 | 5940 |

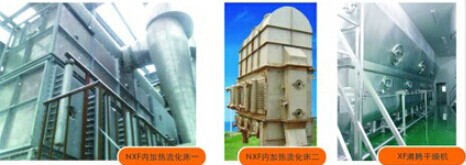

3、XF and NXF boiling / continuous (internally heated) fluidized bed dryers

| Product information: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| It belongs to a square (box) fluidized bed, which adopts the fluidized bed technology of vertical upward flow. The materials move completely irregularly, and the continuous type has the overall movement direction from inlet to outlet. NXF boiling dryer is a high-efficiency and energy-saving dryer whose heat required for dehydration is provided by buried pipe heat exchanger and fluidized hot air respectively. For the dryer of the same size, the drying capacity of NXF is more than 30% higher than that of XF. Cyclone separator, bag filter and pneumatic feeding device can be selected at the same time. Equipment features: economical use of energy, good low-temperature drying performance, small floor area and low system investment. Technical parameters of XF fluidized bed

Technical parameters of NXF internally heated fluidized bed

A型:配旋风分离器;C型:即带旋风,又配布袋除尘器。 |

4、GFG High efficiency boiling dryer / FG boiling dryer

GFG和FG沸腾干燥机 整机实物图

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FG沸腾干燥机 主要技术参数

六、Features of boiling dryer produced by our company: 1. The cylinder is buffered and protected by shell, which is more reliable and safe and has a more beautiful appearance after work; 2. The hopper and separation chamber are made of mirror panel, which is more in line with the sanitary requirements. The main plate is made of coiled plate to ensure the material and thickness; 3. Podou type is adopted for discharging, which is convenient and fast. There is a unique positioning mechanism during feeding, which is not easy to damage the sealing strip and fast feeding; 4. The clutch is adopted, and the contact clutch is simple; 5. The sampler is adopted, with beautiful appearance, convenient sampling and good sealing; 6. The mirror welding method makes it more difficult to deposit materials at the mirror; 7. The air distributor is made with a small fountain for fluidization, which makes the material fluidization easier, the mixing power is smaller, and the service life of the mixing device is longer; 8. Variable frequency control can be selected for mixing, and good quality products can be obtained; 9. Anti static CCP cloth can be selected, and multi bag type is used, which has larger filtering area, can shorten the drying time by one fifth, and the filter cloth is more difficult to stick. The air outlet type is top air, which is more reliable; 10. The whole dryer is integrated, with small floor area and high stiffness. Yangzhou RIFA's business scope is not consumer oriented products. All the contents of the website are for reference only. There are delays in updating and a few clerical errors (please correct). The final contract shall prevail. The content of this website is not advertising, especially technical content. It tends to be discussion and development. The content introduction adopts some patent application publication numbers or paper contents. Professionals are welcome to call and communicate. Refer to the Chinese website, which shall prevail 请参考中文网站,以中文网站为准 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||