Spray drying equipment -- catalogue

1、F-YPLSpray drying small granule preparation line for anti sticking wall

2、LPG centrifugal spray dryer

3、ZLPG Spray dryer for Chinese medicine extract

4、YPG Pressure spray dryer

5、QPG Airflow spray dryer

6、NLP Pressure spray drying granulator

LPGcentrifugal spray dryer YPGPressure spray dryer QPG Airflow spray dryer ZLPGSpray dryer for Chinese medicine extract

喷雾应用示意

糊精压力喷雾 胶原蛋白干燥 陶瓷包衣 陶瓷造粒 玉米浆干燥

Brief introduction of spray drying technology:

Spray drying technology: hot air enters the drying chamber, and the feed liquid (solution, emulsion, suspension, paste liquid) is sent to the spray head of the drying chamber.

There are three basic forms of atomization: LPG centrifugal type, YPG pressure type and qpg air flow type, followed by the evolved ZLPG traditional Chinese medicine extract type and NLP

Optional: constant temperature feeding bucket with stirring; Automatic cleaning tower device.

Equipment characteristics

*The drying speed is fast, and the surface area of the liquid is greatly increased after atomization. In the hot air flow, 95% ~ 98% of the water can be evaporated instantly to complete the drying.

*The product has good uniformity, fluidity and solubility, high purity and good quality.

*The production process is simplified and the operation control is convenient. The liquid with 40% ~ 60% moisture content (up to 90% for special materials) can be dried into powder products at one time.

*The material liquid is atomized into very small mist droplets, which greatly increases the surface area of the material liquid in contact with the hot air. The small droplets exchange heat and mass with the hot air, the water evaporates rapidly, and is dried into powder products in a very short time. The powder particles are collected, and the waste gas is discharged to the outside.

*The drying time is only a few seconds, which is especially suitable for the drying of heat sensitive materials.

*The particle size, bulk density and moisture of the product can be adjusted within a certain range, which is very convenient for control and management.

1、F-YPLSpray drying small granule preparation line for anti sticking wall

The successful development of the production line provides the possibility for spray drying to prepare solid preparations for raw materials with strong hygroscopicity, electrostatic adhesion and thermal viscosity.

The tower diameter and height of the production line are not limited by the gas sweeping arm, with high production efficiency, low energy consumption, extended continuous production time, basically no wall sticking, good product quality, cleaning and improved safety production.

Main features:

(1) Reduce wet sticking of materials

Increase tower height, tower diameter and air wall air device.

(2) Reduce the electrostatic adhesion of materials to the wall

The average particle size of the produced material is 80-300 mesh and 120 mesh, and the particle size is enough to avoid electrostatic adhesion of powder to the wall.

(3) Reduce the hot melt adhesion of materials

On the premise of ensuring the drying strength of the system, the temperature of the material can always be maintained at 50-80 degrees to avoid hot melt sticking to the wall.

(4) The system is sealed, the material loss is less, and the environmental pollution is eliminated.

The dryer operates under micro negative pressure.

(5) The key components of the dryer are easy to replace, and the key control parameters are adjustable to adjust the residence time of materials and meet the needs of multi variety drying.

| Product information: YPG pressure spray dryer features: larger particles, particle size uniformity slightly worse, most of the particles in diameter between 60-150 mesh. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

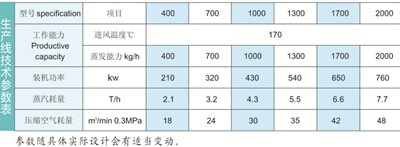

Technical parameters

注:水份蒸发量与物料的特性及进风温度有关,本表参数仅供参考。

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Features: fine particle size and wide distribution. It is suitable for spray drying of sticky and heat sensitive materials such as Chinese medicine extract, enzyme, glue and so on. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

QPG technical parameters

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6、NLP Pressure spray drying granulator

Features: the machine atomizes the materials into small droplets through hydraulic pressure, enters the pressure nozzle, convective drying with hot air in the tower to obtain granular products.|

NLP technical parameters

|

Yangzhou RIFA's business scope is not consumer oriented products. All the contents of the website are for reference only. There are delays in updating and a few clerical errors (please correct). The final contract shall prevail.

The content of this website is not advertising, especially technical content. It tends to be discussion and development. The content introduction adopts some patent application publication numbers or paper contents. Professionals are welcome to call and communicate.

Refer to the Chinese website, which shall prevail

请参考中文网站,以中文网站为准